Picking the right paint booth airflow style will be the most critical decision you’ll need to make when you make up your mind to purchase a unit. It is always prudent to take all the time you need to make an informed decision since choosing the wrong solution will greatly impede your unit’s overall efficiency and productivity. Selecting the ideal spray booth airflow style will set you up for consistent and long-term success and enable you to obtain a good ROI.

Paint booth laminar airflow

The most mission-critical objective of using a spray paint booth is achieving what is referred to as laminar airflow. Essentially, this is the state where air is relayed within a unit at the same velocity and direction, with decreased air-stream crossovers. To be able to achieve laminar airflow, you will need to increase the number of filters in the booth to guarantee the efficient filtration of particulates. Also, a paint booth that is completely engineered is designed to maximize paint application transfer efficiency along with overspray capture.

Once a unit attains laminar airflow, a stream of air draws overspray and other contaminants away from the object being finished. This ultimately culminates in consistently top-notch paint job finish quality and eliminates the necessity for performing many reworks.

Paint booth pressure balance

This is yet another important thing to always consider when choosing the paint booth air flow that is right for your unique needs and preferences. In this particular state, the level of air drawn within the unit is always the same as that that’s expelled from it. The moment a booth is unbalanced, its filters will capture more paint particles. Once they get clogged, the exhaust fan will fail to eliminate contaminated air since it will experience excessive resistance to its usual operations. It is very important to note that achieving a balanced air pressure in a non-pressurized spray booth is not possible.

Alternatively, pressurized units, besides exhaust fans, come with intake fans. When coupled with dampeners or variable frequency drivers, these fans will be in a good position to enable your booth to attain and maintain the right pressure balance. Let’s now take a closer look at some of the most popular spray paint booth airflow styles you might like to look into.

Cross-flow paint booths

In this configuration, air is drawn into the unit at the front through either a filtered door or plenum. Once inside, this air is relayed to the opposite end of the booth. This variety of paint booth, when compared to other solutions, usually functions at a decreased cubic feet per minute. Since they come complete with diminutive and fewer fans, diminutive air makeup units, and fewer filters, cross-flow units are an especially pocket-friendly option.

However, the potential for cross-contamination in such a booth is always greater than most other alternatives. It then becomes extremely hard to control overspray, particularly in a long unit. Should you need to finish multiple objects lined up in the unit, overspray can easily be drawn across the successive objects, which immensely impairs the quality of the paint job. This high risk for contamination is attributable to the longer lengths overspray must travel in a cross-flow unit.

Side downdraft paint booths

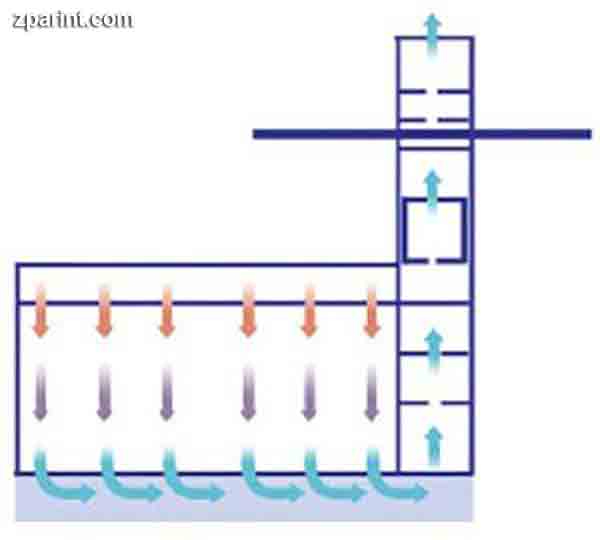

This kind of spray booth boasts of a slightly superior and uniform airflow upon comparison with the cross-flow variety. In this configuration, the ceiling is filtered and the exhaust plenums stretch across both sides of the booth. This, in turn, ensures the airflow is more consistent from end to end. In a side downdraft spray paint booth, the air is relayed downwards towards the object being painted and is eventually expelled through the floor level plenums to deliver more contamination control.

Another plus is you won’t have to install concrete pits for a side downdraft unit when contrasted with the pitted downdraft varieties. This can result in cost savings of over $5,000. On the downside, this sort of paint booth lacks a large footprint. Additionally, the paint operator is always at a risk of getting hit by overspray once air is drawn into the exhaust chamber.

Pitted downdraft paint booths

The pitted downdraft spray booth possesses arguably the most superior airflow style when it comes to effectively controlling overspray and contamination. As is the case with the side downdraft unit, this solution can achieve uniform airflow thanks to a full length and filtered ceiling and exhaust pits which stretch across the entire floor. In this configuration, air is relayed downwards, but when compared with a side downdraft booth, it never has to fight gravity or even pass close to the paint operator. Rather, this air is drawn together with overspray towards the exhaust pits.

When contrasted to the cross-flow spray paint booth, the pitted downdraft unit is around 25% more costly, even when you exclude the cost for the concrete pits. However, these kinds of units deliver the finest and most consistent finish quality.

ZPar International is a leading manufacturer of diverse quality paint booths that integrate all of the different airflow styles outlined above. This includes the cross-flow, semi-downdraft, side downdraft, and pitted downdraft varieties.