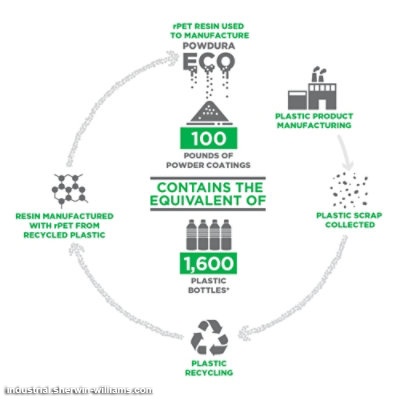

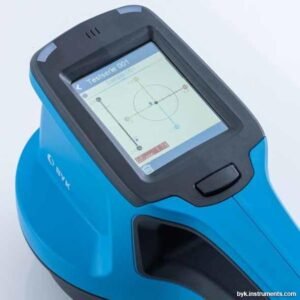

The COVID-19 pandemic slowed down the flow of new innovations and technological developments in the powder coating industry. However, since most of these programs were already in progress prior to the pandemic, some have begun to come to fruition with the stabilization of the market landscape. This includes the emergence of low-temperature curing powders, which can now meet even the most stringent durability thresholds including AAMA, and QualiCoat class 3 standards. There have also emerged powder coating technologies that are specifically centered on boosting sustainability such as recycled plastic feedstocks and bio-based raw materials. Also, the industry has introduced binders which demonstrate highly improved corrosion resistance as well as edge coverage, not to mention several advances gained in powder coating application control technologies.

Using this line of powder coats, you will be able to significantly minimize your paint facility’s overall energy consumption and boost the productivity of your powder coating application processes. In turn, this will enable you to reduce your operational costs and your shop’s environmental footprint.

Let us now take a look at some other powder coating technological trends that have come into the limelight in the last 2 years or so.

Powder coating instrumentation and innovations

ZPar International is a foremost manufacturer of high-quality powder coating solutions such as batch powder units, cartridge batch powder units, and industrial batch oven curing solutions. We also offer diverse paint booths, spray booths, and spray paint booth units that incorporate some of the most popular airflow patterns in the market. Give us a call today!