Paint booth automation

In the recent past, automation in the spray paint booth world has been able to bring many substantial improvements in the sector. The utilization of robotic painting systems has been shown to deliver unheard-of benefits in this business. This, of course, includes offering extremely consistent paint job outcomes, over the passage of time. Even the most experienced and skilled paint booth operator can hardly guarantee consistent error-free performance over time.

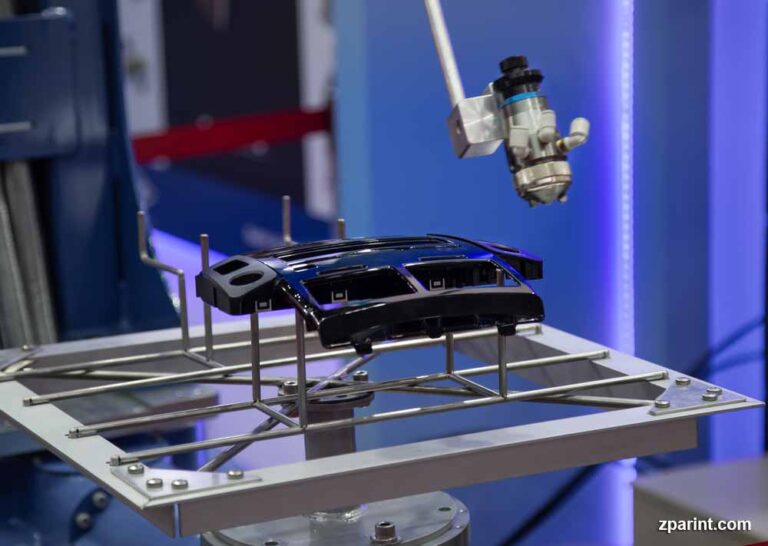

Automation in the spray paint booth environment also goes a long way in totally eliminating human error from the equation in ways you might never have deemed possible. Alternatively, one of the worries that make many industrial businesses hesitate in investing in robotic technology is the logical fear that such machines cannot replicate precise human movement while engaged in certain painting processes. Nevertheless, there are now robotic systems which incorporate what is known as “self-learning” programming.

This emerging technology enables skilled paint booth operators to literally demonstrate to these machines how they ought to move. For example, such robots may be “taught” the right way to apply either liquid paint or powder coatings. They can as well learn how to use a blow-off or suction gun properly. This way, these machines can effortlessly receive training in real-time, and ultimately be able to master the paint operator’s elaborate movements.

Today’s automation technology is in a good position of significantly improving overall spray booth efficiency rates without in any way compromising on paint job quality. Very recently, an Italian company introduced an automated painting and finishing robot which integrates 2 spray guns on a single arm. This ingenious setup more than doubles the coverage rate of a normal human paint operator. Additionally, this particular machine is in a position of applying paint and even coatings on products which are no more than 6” tall.

Lastly, yet another promising robotic painting system innovation is Burr’s “ Paint Shop of the Future” EcoProBooth concept. This sort of spray paint booth may significantly cut downtime by simply enabling your operators to carry out routine maintenance tasks and cleaning paint application technology, without in any way impeding production runs. It is specifically designed to immensely minimize energy consumption and VOC emissions. While at the same time, boosting paint job efficiency by blending interior and exterior operations into one workstation thanks to its novel series of box layouts.

Paint booth airless electrostatic paint atomizers

Over the course of the month of March this year, the acclaimed Japanese automobile maker, Toyota, unveiled a one-of-a-kind paint atomizer, which utilizes static electricity rather than air. This is a stark contrast from the traditional air atomizers that are currently in widespread usage all over the globe. This novel device has demonstrated more than 95% coating efficiency, which is currently the highest worldwide. For those who might be in the dark, the average conventional air atomizers, can at best, deliver efficiencies of between 60% to 70%. At the same time, the traditional varieties of these products usually leverage aerodynamic force. This, in turn, always results in paint particles being scattered and ricocheting on the object being painted.

The new spray paint booth technology leverages electrostatic atomization to guarantee the charged paint particles gravitate towards the object being painted. It is important to note that electrostatic atomization along with electrostatic painting technology, when combined, can immensely minimize the number of scattered atomized paint particles. All in all, this makes sure that paint booth operators can achieve much higher overall paint job efficiency as demonstrated in the new Toyota device. Another prominent feature of this specific product includes a rotating cylindrical head, which sets to work by optimizing the amount of paint being sprayed. It also boasts of an extremely accurate current control capability, which makes premium close-range paint jobs more feasible.

ZPar International is a leading manufacturer of a variety of industrial paint booths including

open-front, cross-flow,semi-downdraft,side-downdraft, pitted downdraft varieties, and more.