As with all businesses, the COVID-19 pandemic caused stunted growth in the international industrial paint booth market that is projected to gradually improve in the foreseeable future. Thanks to the lockdowns that were imposed globally, many spray booth manufacturing facilities were and still are shut down. Also, the complications of the pandemic gave rise to a global supply chain crunch which is mainly attributable to the restrictions on movement that were established when the pandemic struck. In turn, this has caused a shortage of raw materials which has curbed industrial paint booth production at a substantial rate.

Yet, there is a silver lining in all this. COVID-19 has also fast-tracked so many developments in the industry that were already in the works including weaning the west from the overdependence on China-made raw materials. Also, to effectively deal with the stiff competition and fragmented aspects that characterize the international industrial spray paint booth sector, many players are beginning to adopt newer strategies. This includes forming partnerships, mergers, and even collaborating with each other on projects. These strategies have enabled most of them to reach out to untapped markets and access the resources, which will boost their sustainability and overall success. The international industrial paint booth sector is now expected to register a compound annual growth rate of 2.6% from 2019 to 2027 and will be worth $789 million by 2030.

The automotive industry is still recovering

The downdraft segment’s steady growth

The Asia Pacific Excluding Japan (APEJ) will continue to dominate the global industrial paint booth industry

Emerging technology trends in the industrial paint booth sector

Additionally, there is a growing shift in the industrial paint booth sector towards waterborne coatings. Powder coating is growing in popularity, particularly in those applications where waterborne coatings could be undesirable. Another interesting trend is the adoption of fusion bonded epoxies that depend on advanced resins and toughners to be able to fully maximize desired performance characteristics. This includes flexibility, performance in extreme temperatures and pressures, impact strength, and resistance to chemicals and UV radiation.

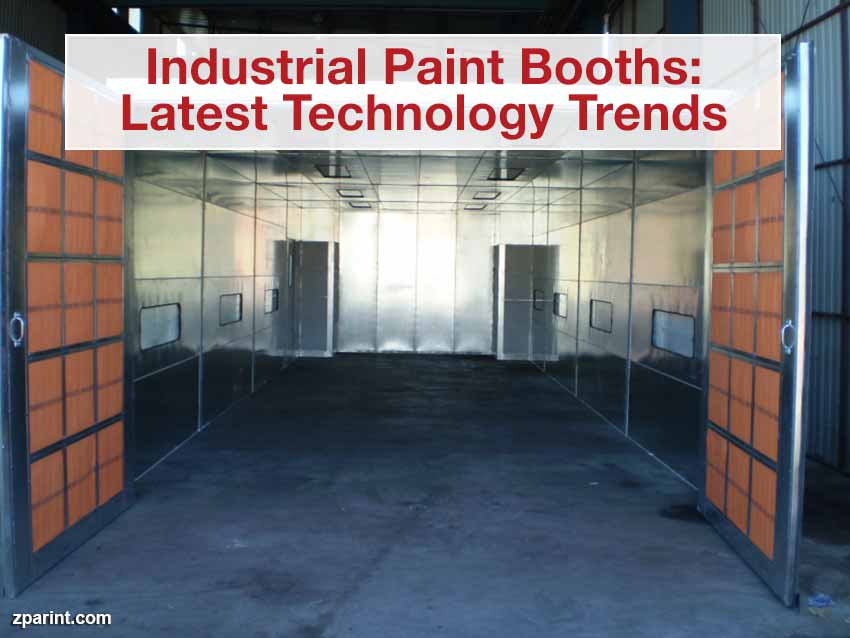

ZPar International is a leading manufacturer of many standard and custom paint booth solutions including the industrial , open front, crossflow, semi downdraft, pitted downdraft and side downdraft varieties. We also offer top-notch powder coating units, abrasive blasting equipment and spray booth accessories.