As the owner of an industrial paint shop, it is important and beneficial for you to focus on the things, big or small, that you can do to minimize your facility’s overall impact on the environment. While, at the same time, work on viable business strategies which may enable you to formulate plans for sustainable growth. In recent years, paint booth technology has drastically evolved to help more in the efforts to decrease energy consumption and make the operations of these units more efficient. This trend has also facilitated a much more effective paint environment. Besides minimizing the actual impact on the environment in spray booth operations, the widespread utilization of these innovations has culminated in cleaner, brighter, and infinitely more productive paint shops the world over. Here then are some of the most notable things you can do to ensure your spray paint booth uses less and even cleaner energy.

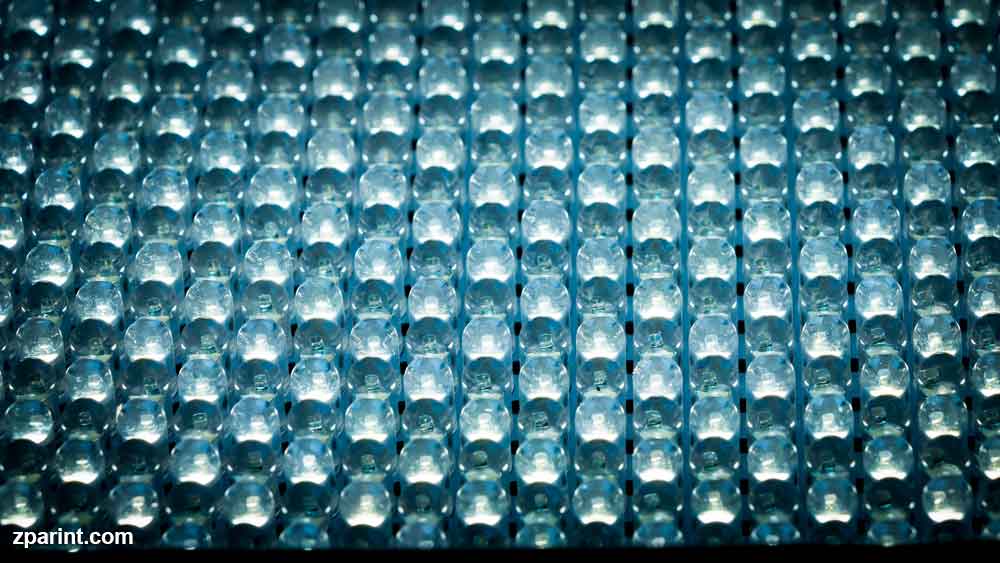

LED lighting

Integrating LED lighting in your paint booth may prove to be a simple and pocket-friendly means of saving energy in your facility. Also, this innovative technology can be seamlessly incorporated into other key finishing systems in your booth to realize more cost savings on your shop’s overall energy bills over time. Some LED lighting are well noted for delivering substantial energy savings of up to 40% upon comparison with conventional fluorescent lighting systems.

. In turn, decreased energy consumption in your spray booth will result in quicker payback time, which makes it, now more than ever, cost-effective to invest in LED lighting. Lastly, since this sort of lighting utilizes existing electrical wiring, so you won’t have to foot any rewiring costs in your paint facility.

Water-based paint

Water-based industrial paint is, without doubt, much less toxic than solvent-based paint. As such, traditional basecoats usually carry a volatile organic compound (VOCs) content of no less than 84%. On the other hand, the average water-based basecoat carries a VOC content of no more than 10% solvents.

Electric infrared curing technology

Infrared spray paint booth curing technology is widely acclaimed for optimizing paint shops’ throughput, simply through delivering substantial time savings than conventional cure cycles or even using traditional dryers. In the case of gas-powered infrared systems, catalytic reactions lead to significantly decreased cure times. Nevertheless, this can only be realized the moment the units are pre heated to temperatures of 200oF that necessitates at least 15 minutes. To effectively deal with lost time during the warmup periods, gas-powered units are usually left activated all day long.

This results in the consumption of great amounts of energy. On the flip side, the utilization of shortwave electric infrared paint booth curing technology results in much less energy consumption because it delivers remarkably quick drying times. This generally minimizes the need for reworks in paint job operations. Additionally, these systems can reach the ideal curing temperature levels nearly instantaneously and cure repairs immediately. Finally, cooldown processes are extraordinarily fast when using electric infrared spray booth curing systems. This certainly means these systems may be activated whenever necessary and can even be handled safely in shorter times after deactivation.

Powder coating

Embracing powder coating spray paint booth technology can be another great way of significantly minimizing the environmental impact of your paint facility. When compared with liquid coating solutions, powder coating doesn’t release VOCs, solvents, or for that matter, any toxic materials into the atmosphere that are heavily present in paint fumes. What’s more, powder overspray may be recovered and even reused in a markedly convenient and stress-free manner. All in all, the waste created by the powder coating process is little and may be disposed of easily and more importantly, safely.

Energy-saving paint booth systems

When air is expelled from a paint booth finishing equipment, heat is lost too. To this end, there are now heat recovery systems which are specifically designed to recover the heat that is lost with exhausted air. Investing in such systems can be yet another excellent way of achieving additional energy savings in your paint shop operations. Some of the best heat recovery systems out there can recover upwards of 50% of lost energy from air makeup units that are used for either heating or cooling. On the other hand, some spray booth control panels integrate inbuilt economy mode functionalities. This given innovation sets to work by automatically ramping booth operations down and running on idle whenever the unit isn’t been used. Also, these systems can make use of outside air when the energy-saving feature is activated. In turn, this ensures clean air circulates in the spray paint booth at all times.

Government-sponsored programs

There are now a number of government-sponsored initiatives that enable small and growing companies to purchase efficient and code-compliant paint booths. Besides boosting your paint facility’s throughput and the finishing quality of your paint booth, a code-compliant unit will also help you to do your part in conserving the environment. On a parting shot, other eco-friendly innovations you could embrace can include fully automated integrated spray booth processes that do away with drying phases of paint jobs. There are also dry separation systems which effectively control overspray and eliminate the need for water and chemicals, or even purification systems for exhaust air before it is expelled from the unit.

Zpar International is a foremost manufacturer of a variety of paint booths including the automotive, industrial and outdoor varieties. We also offer top-notch and intuitive customer support to all our customers to ensure your purchased units operate efficiently and cleanly at all times. Give us a call today at 866-519-7269!