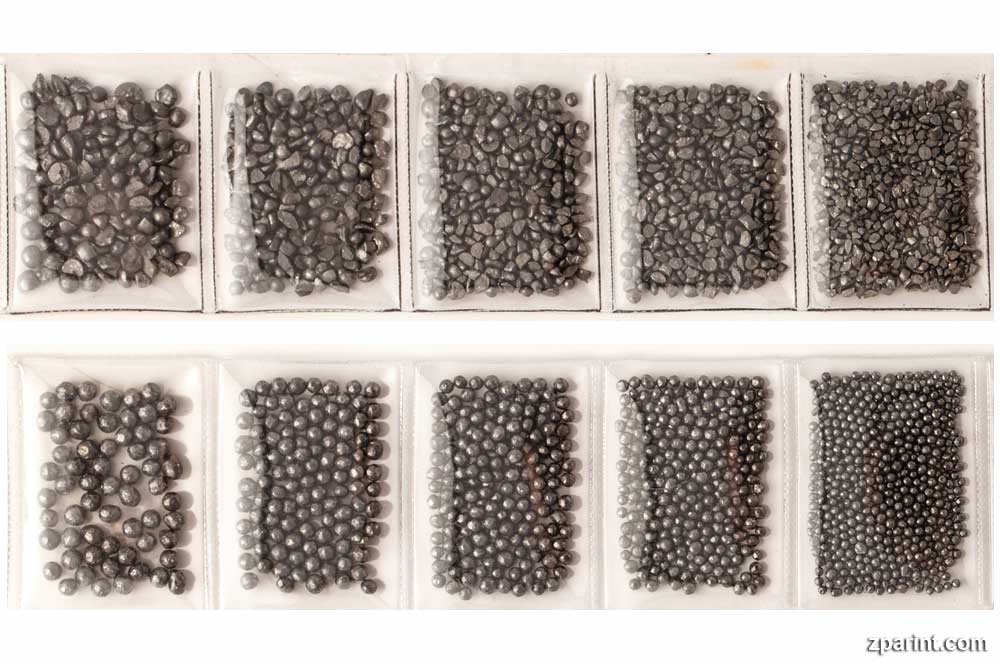

Pick the right abrasive blasting materials

Safeguard your HVAC system

Tarp your outdoor abrasive blasting work areas

After work cleanup

Environmentally-friendly abrasive blasting operations are never complete without a thorough post-work cleanup process. During this phase, all cleanup actions you take must be implemented to make sure that equipment, property, and areas impacted by the abrasive blasting operation are restored to their pre-work cleanliness. You should also collect waste materials from the process and ensure they are disposed of properly. Should there be any sort of waste that is judged to be particularly toxic, it should then be disposed of in strict accordance with the laid down guidelines that dictate such hazardous disposals. Should you be working with a contractor who lacks the mandatory experience in dealing with hazardous waste disposal, you should consider enlisting the services of an experienced toxic waste disposal firm that can do a professional job.

ZPar International is a foremost maker of first-rate abrasive blasting equipment such as a variety of blasting enclosures, dust collection systems, abrasive blasting reclaim systems and more. We also offer quality paint booths, and spray booths that incorporate the most popular airflows in the market.