Paint booth intake filters

Spray paint booth intake filters go to work by cleansing the air which is introduced into the unit. In turn, this substantially eliminates the risk of contamination of paint job finishes through microscopic dust and particles. Typically, the best intake filters for your spray booth will largely be dependent on the exact airflow you eventually settle for. For instance, a crossflow unit necessitates 2-layered takified media panels. Alternatively, high-efficiency diffusion media panels are usually standard for most downdraft booths.

Paint booth exhaust filters

Ideally, spray booth exhaust filters are designed to trap overspray as well other contaminants to prevent the contamination of paint job finishes. They are also critical in ensuring the safety of your paint operators while they perform their duties within your unit. Lastly, the best paint booth exhaust filters made available in the market play a critical role in protecting the environment against toxic overspray and other contaminants. In most booths, the air exhaust system uses a single-stage filtration process as opposed to the dual-stage filtration common with air intake systems.

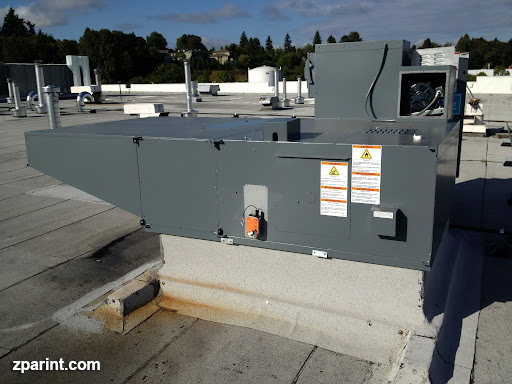

Paint booth air makeup units

Spray paint booth air makeup units are designed to deliver an affordable source of air replenishment in a unit and come complete with heaters, motors, blowers, filters along with other auxiliary components. Depending on the exact layout and size of your spray booth, you ultimately select the ideal air makeup unit for you should deliver a suitable volume and flow of air. In turn, this will go a long way in significantly eliminating issues such as drafts and stale or contaminated air within your unit.

ZPar International provides top-notch spray booth air handling component solutions as well as a variety of paint booth options for virtually any painting application you might have in mind.

For more information on ZPar air handling systems, please visit