Key factors that influence paint booth sizing

In the first place, the size of these products can prove to have a significant impact on their operational costs. To this end, the bigger the dimensions of a unit are, the more intake and exhaust air will have to be forced through it. As such, a crossflow booth’s airflow design can need a 10×10 cross section for proper airflow. Alternatively, a downdraft unit will require a 20×10 cross section for air to flow in it and ultimately vented out appropriately. This definitely means the latter solution will need two times more intake and exhaust airflow which increases its overall operational costs. On the other hand, you may be forced to pick a certain spray booth size for safety purposes.

Industrial paint booth sizing

As with other types of spray paint booth applications out there, when you’re considering the suitable size of an industrial unit, you will first need to determine the exact sizes of the products that will be finished in it. This will ensure there is always sufficient space as well as proper airflow in the unit. Generally speaking, the best practice in choosing the size of an industrial paint booth is figuring out the exact dimensions of the biggest object to be painted, and afterward adding no less than 2 feet to its height, 5 feet to its width, and 6 feet to its depth. You will as well have to factor in the various dimensions of equipment like pallets, carts, and racks. Finally, if your operators finish multiple parts simultaneously, you will need to incorporate at least 3 feet of empty space in between the objects that will be finished.

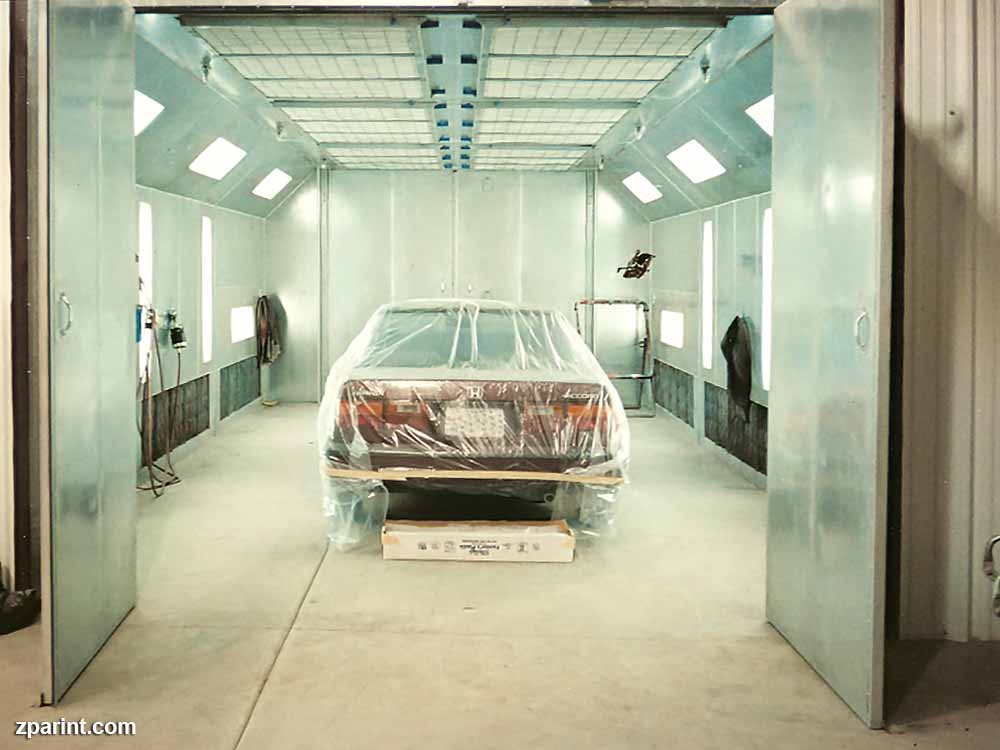

Automotive paint booth sizing

Typically, the size of an automotive spray booth tends to be much more standardized when compared to other applications. The average automotive unit comes complete with a length of between 24 to 30 feet, a width of 14 feet, and a height of 9 feet. You may settle for a higher height if you wish your spray paint booth to be used in finishing taller vehicles. Lastly, you will have to ensure your unit dimensions fits the range of ETL listed sizes to guarantee code compliance over time.

Aviation paint booth sizing

For an aircraft paint booth, you will need to figure out the exact dimensions of the biggest aircraft that will be finished in your facility, and then add no less than 10 feet on all sides for proper clearance. You should as well factor in extra space to enable your spray booth to comfortably accommodate essential equipment like scaffolding and personnel lifts.

ZPar International is a leading manufacturer of top-quality paint booths in the country, and our expertise can be of great use to you when it comes to determining the best size for your spray booth regardless of the application you have in mind. For more details about our spray paint booth offerings, visit us here