Blog

Maximizing Productivity with an Efficient Batch Oven Workflow

Maximizing productivity while maintaining product quality is crucial for staying competitive. Batch ovens play a vital role in manufacturing processes, particularly in aerospace, automotive, and metal coating industries. However, an efficient workflow around batch oven operations can significantly enhance productivity and efficiency. Today, we will delve into optimizing your batch oven workflow, focusing on essential aspects such as loading capacity, temperature uniformity, curing cycles, and material handling. Understanding the Importance of Batch Ovens Batch ovens are versatile and used for various applications, including curing, drying, baking, and heat treatment. Effectively using batch ovens requires careful consideration of several critical factors

Choosing the Right Paint Booth Filters for Your Application

Maintaining air quality and overspray control is crucial in industrial finishing. The right paint booth filters enhance efficiency and safety across various applications, from automotive to furniture. This guide covers filter types, efficiency ratings, and replacement schedules to help you choose wisely. Understanding Paint Booth Filters Paint booth filters are an essential element of paint booths. They capture overspray, dust, and other particles, ensuring that airflows remain clean and environments are safe for both operators and the final painted products. The primary function of these filters is to capture particles, contributing directly to maintaining the desired quality of air and

Abrasive Blast Booth Maintenance: Keeping Your Equipment in Top Condition

In industrial finishing, abrasive blast booths are crucial equipment that play a significant role in achieving desired surface preparation and cleanliness. Regular maintenance of these booths is not just recommended, but essential for optimal performance and to extend their longevity. The following guide explores how to maintain your abrasive blast booth, focusing on critical aspects such as abrasive recovery, dust collector maintenance, and other tasks that keep your equipment functioning at its best. The Importance of Regular Maintenance Abrasive blast booths are integral to many industrial processes, offering consistent results in surface finishing. However, like all heavy machinery, they are

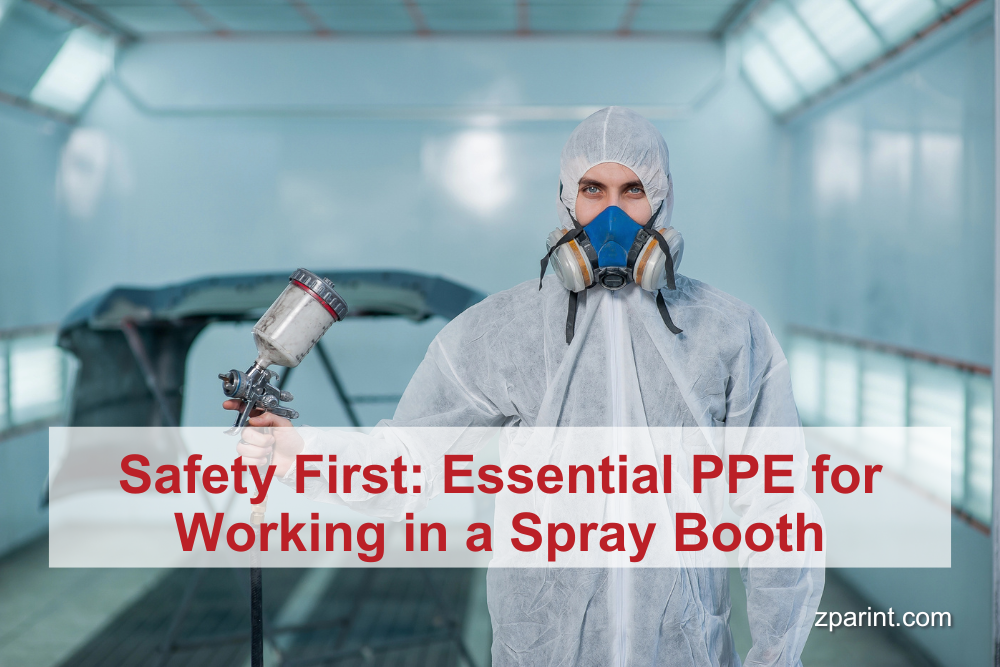

Safety First: Essential PPE for Working in a Spray Booth

Safety is paramount in a spray booth, where paint particles and fumes pose serious risks. Proper PPE—respirators, protective clothing, and eye protection—is essential for worker safety. Today, we will cover the key PPE needed to stay protected. The Importance of Personal Protective Equipment in Spray Booths Spray booths are environments designed for painting and finishing tasks, where paint is atomized and applied through spray guns. While these booths ensure controlled environments to achieve quality finishes, they also pose hazards that demand rigorous safety protocols. Workers can be exposed to harmful chemicals and particulate matter without proper protection, leading to respiratory

Batch Oven Efficiency: Tips for Reducing Energy Consumption

Managing energy consumption is beneficial for the environment and crucial for the bottom line. Industrial batch ovens are fundamental in manufacturing operations, often used for curing, drying, or baking processes. However, their energy demands make them a focal point for efficiency improvements. Today, we will explore methods to reduce energy costs while improving the efficiency of your batch oven, providing practical tips for optimizing temperature control, insulation, and airflow. Understanding Batch Ovens and Their Role Batch ovens are used to cure coatings and adhesives in various industries, including automotive, aerospace, and electronics. They differ from continuous ovens in that they

Improve Your Finish: Optimizing Airflow in Your Spray Booth

In professional painting and finishing, achieving a flawless finish isn’t just about selecting the right colors or top-quality paint. It’s a meticulous process that demands attention to the finer details, especially when optimizing airflow in your spray booth. As technology in the industry advances, spray booths, often called paint booths, have become crucial for enhancing efficiency, safety, and the ultimate quality of the paint application. Let’s dive into how proper booth ventilation, air pressure, and a sound filtration system can make all the difference. The Vital Importance of Airflow in Spray Booths The primary objective of a spray booth is

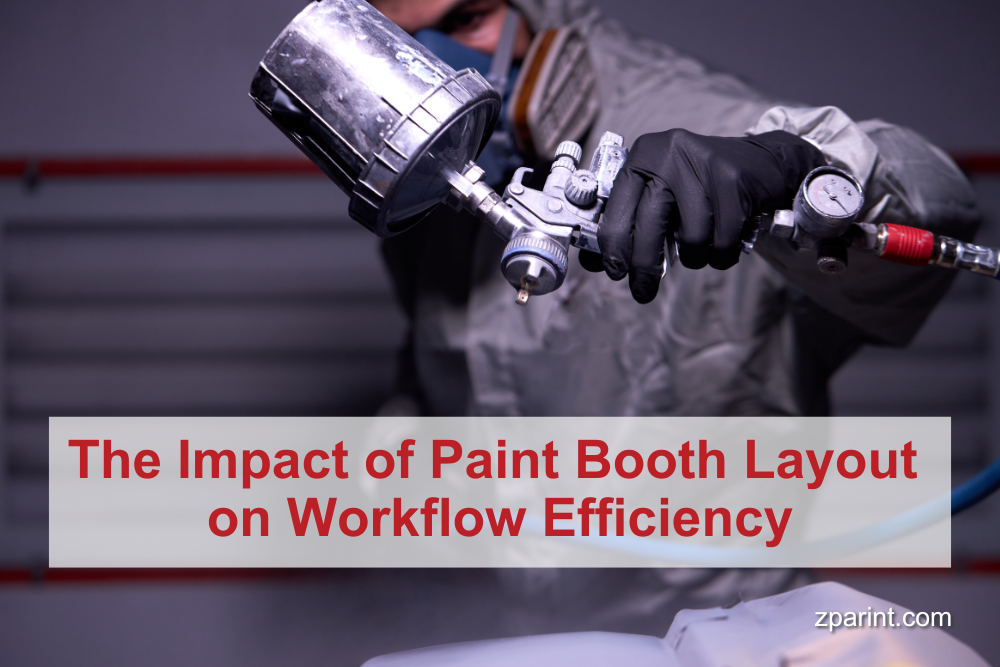

The Impact of Paint Booth Layout on Workflow Efficiency

When it comes to industrial painting solutions, the layout of your paint booth plays a crucial role in maximizing workflow efficiency. Whether you’re using a spray booth, powder booth, or abrasive blast booth, a well-thought-out layout can significantly boost productivity, reduce downtime, and ensure smooth operations. By focusing on space utilization, optimizing equipment placement, and addressing potential production bottlenecks, you can create a streamlined, efficient workflow that keeps your operation running smoothly. From space utilization to eliminating production bottlenecks, let’s explore how paint booth design impacts your entire workflow. Optimizing Space Utilization Effective paint booth design starts with how you

Latest Technologies in Overspray Capture and Management

In the world of industrial painting, managing overspray efficiently can make or break the quality of your work. With advancements in spray booth technology, staying up-to-date on the latest innovations is key to keeping your workspace clean, productive, and eco-friendly. Whether you’re using a paint booth, spray booth, or powder booth, the right tools can transform your operations. Read on to discover the most innovative solutions that are shaping the future of overspray capture and management. Advanced Air Filtration Systems Keeping the air clean in your workspace has always been a priority, but now, air filtration systems are doing more

Choosing the Right Abrasive Blast Booth for Your Needs

In industrial finishing, surface preparation is pivotal in ensuring the quality and longevity of coatings and finishes. An abrasive blast booth is fundamental in achieving optimal surface preparation. Whether you want to refurbish metal, prepare surfaces for painting, or remove contaminants, choosing the right blast booth is crucial for efficiency and effectiveness. This guide will explore the different types of blast booths, abrasive media, and safety considerations, helping you make an informed decision for your surface preparation needs. Types of Abrasive Blast Booths When selecting an abrasive blast booth, it’s essential to understand the different types available. Each has unique

Top 5 Maintenance Tips to Extend the Life of Your Paint Booth

Paint booths, or spray booths, are essential in industries requiring precise and high-quality paint jobs. Whether used in automotive, aerospace, or other manufacturing sectors, maintaining these booths is crucial to ensure they function optimally and last for many years. Here, we’ll explore five essential maintenance tips to keep your paint booth running smoothly while extending its lifespan. Regular Filter Replacement One of the most critical components of a paint booth is its filters. They are vital in capturing overspray and maintaining clean airflow, ensuring harmful particles do not escape the environment. Regular filter replacement is crucial to maintain an efficient

Selecting the Ideal Coating Method for Industrial Applications

In industrial manufacturing, the coating process is a crucial stage that can significantly impact the quality and durability of the final product. Whether you’re dealing with large machinery, automotive parts, or consumer electronics, choosing the right coating method can make all the difference in protecting your investment and ensuring customer satisfaction. We will help you navigate through the factors to consider when selecting the ideal coating technique for your specific industrial needs. Understanding Your Options Before diving into the details, it’s important to understand the various coating methods available. Common techniques include: Paint Booth: Utilized for liquid coatings, this method

Achieving Superior Finish Quality: Tips for Optimizing Your Paint Booth

In the industrial painting industry, achieving a superior finish is a testament to the efficiency of your paint booth setup. Whether it’s a paint booth, spray booth, or batch oven, the key lies in optimizing the operational parameters to ensure high-quality output. Allow us to provide you with practical tips for maintaining your paint booth and achieving impeccable results. Airflow Control: Ensuring Consistent Results Airflow is a crucial element in optimizing paint booth efficiency and achieving a uniform finish. Controlling airflow effectively can lead to: Consistent Temperature and Humidity: Maintain stable temperature and humidity levels inside the booth to ensure