Why is automation a key growth driver in the paint booth market?

Robotics is not a new concept in the spray paint booth world. Robots have been made use of in finishing numerous industrial products for decades on end. With the passage of time, robotic technology has registered great leaps in innovation and enabled them to deliver many value-added benefits to the whole industry. This, of course, includes substantially improving paint booth operational productivity, efficiency, sustainability, and more recently led to waste reduction.

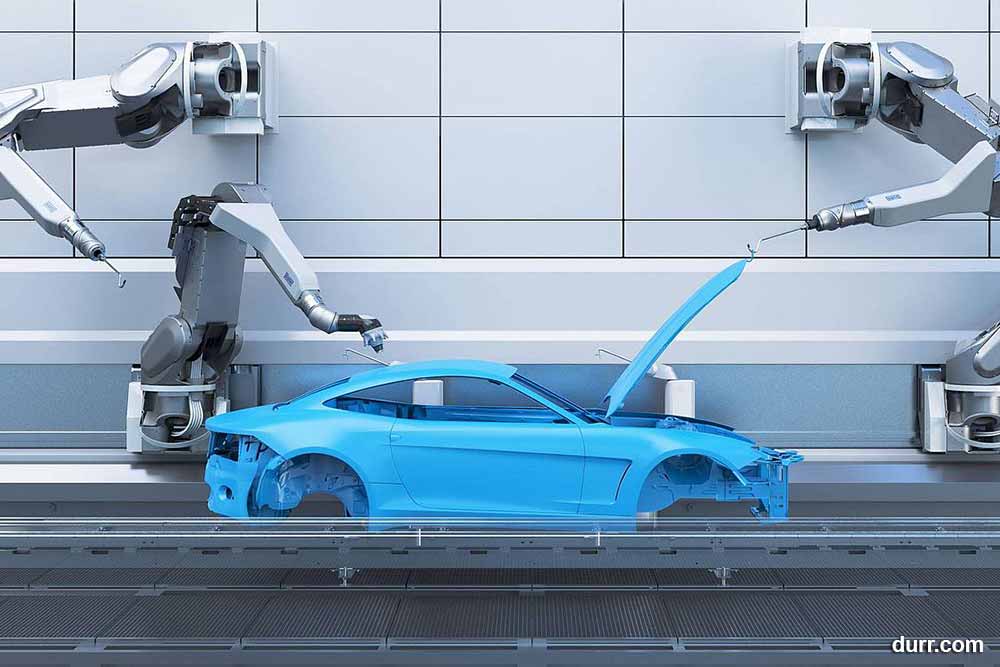

EcoProBooth: Paint Shop of the Future

Earlier this year, Durr (one of the leading global players in spray booth automation technology) introduced its Paint Shop of the Future concept. The key attraction of which is the EcoProBooth unit that has received sensational reviews for its novel features. This spray paint booth leverages a distinctive box layout, which facilitates unheard-of flexibility in adapting it in accordance with the growing number of different vehicles automakers produce.

The EcoProBooth’s modular configuration permits converting and extending it to suit a paint booth’s evolving production requirements. In particular, this unit is well noted for being able to accommodate diverse cars, ranging from compact models to medium-size sports utility vehicles.

Additionally, it incorporates both interior and exterior finishing processes all in one workstation. While, at the same time, making use of a grand total of 8 robots and 4 selective compliance assembly robotic arms (SCARA). As a bonus, this innovative spray booth has been designed to facilitate the carrying out of routine maintenance and cleaning operations without in any way interrupting production runs. To this end, it comes complete with a number of service cubicles which are situated at all corners of the unit. These given cubicles go a long way in allowing technicians to either clean or replace application technology without having to enter the workspace itself. Should any of the robots at any time require maintenance, it will simply pass its arm through specially made windows into the service cubicles. Lastly, the application space, on its part, has been designed to optimize air recirculation in order to minimize carbon dioxide emissions and energy utilization.

ABB’s PixelPaint Overspray-Free Technology

ABB recently unveiled its incredible PixelPaint Overspray-Free Technology that has taken the spray paint booth industry by storm. This solution utilizes an inkjet head as opposed to the usual spray approach in the finishing process.